|

|

| |

| 상품정보 |

|

|

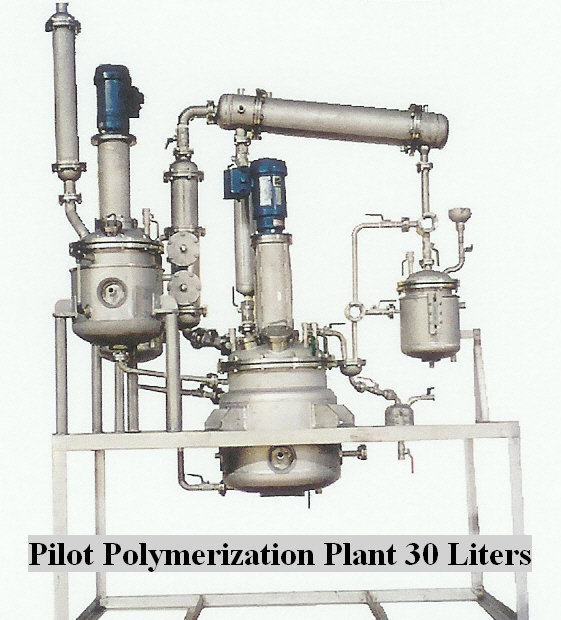

연구소·소규모 생산용 파일러트 만능 중합 반응장치/Pilot Polymerization Plant(Pilot Reactor)

|

|

|

|

|

|

Click to enlarge image Click to enlarge image |

|

제품특징

- Multi-Purpose Reactor For Synthetic Resins

Product Features

- In the course of process,

equipment in contact with materials will be manufactured by stainless steel.

- Thelarge-sized reactor available up to 30,000 litres and

the small-sized pilot reactor available from 20 litres to 500 litres can be

provided upon request.

- A wide speed control range of 0-174 r.p.m. by inverter.

- Typical universal reactor with hydrostatic agitation, vacuum

system, azeotropic condenser, inert gas, thermal oil heating, fully controlling

system, Complete automation system with complete controlling, recording and

surveillance panels as well as computerized controlling processes can be applied

to this reactor.

- Internal cooling coil and two-section external limpet type

heating coil or jacket. Heating of this reactor by the independent thermal

fluid circulating system with automatic temperature controlling of contents

of this one.

- Reaction vessel constructed with STS 304 quality stainless

steel with 50A n.b. internal cooling coil, 50A n.b. half-piped limpet coils

externally arranged in two sections to enable batches at the ratio of 1 to

2 in volume to be processed. Three cooling coil support act as a baffle to

assist agitation.

- Vertical geard type agitator, flame-proof eG3 motor, a variable

speed range of 0-174 r.p.m./min., helical spur reduction gear box, chain coupling,

fabricated support stuffing box with sealed bearing and packed gland or M/C

seal assemble, stainless steel raised face clamp mounted on flange, stainless

steel stub shaft assembly with flanged coupling to suitable for diameter of

agitator shaft, rake style foam breaker with sprit hub, one plain paddle and

two four-blade turbines also with sprit hub, gland packing to with stand operating

temperatures of up to 300'C.

- Horizontal cylindrical shell and tub single pass condenser

constructed with ST304-316 stainless steel tubeplates, tubes and headers with

carbon steel shell or stainless steel shell.

- Vertical cylindrical decanter of suitable volume capcity

and tube single pass condenser constructed with ST304-316 quality stainless

steel complete with sight and light glass ports, vapour and reflux connections,

drain valve and late additions vessel.

STANDARD SPECIFICATION

|

MODEL

|

Dimension

|

Charging

Amount

|

Driving

Power

|

Heating

Area

|

Height

of

Heating Jacket

|

Decanter

|

Reflus

Condenser

|

Cooling

Water

|

|

l

|

Dmm

x Lmm

|

l

|

kw

|

m?

|

mm

|

l

|

m?

|

m?/Hr

|

|

DSRT-500L

|

800

x 1000

|

400

|

1.5

|

2

|

650

|

60

|

3

|

4/Hr

|

|

DSRT-1000L

|

950

x 1300

|

700

|

2.2

|

3

|

850

|

80

|

5

|

7/Hr

|

|

DSRT-1500L

|

1200

x 1300

|

1200

|

3.7

|

4.5

|

850

|

100

|

7

|

9/Hr

|

|

DSRT-2000L

|

1300

x 1400

|

1500

|

3.7

|

5

|

950

|

150

|

10

|

13/Hr

|

|

DSRT-2500L

|

1400

x 1500

|

1900

|

5.5

|

6

|

1000

|

150

|

12

|

16/Hr

|

|

DSRT-3000L

|

1500

x 1600

|

2300

|

5.5

|

7

|

1050

|

200

|

15

|

20/Hr

|

|

DSRT-4000L

|

1600

x 1800

|

3000

|

7.5

|

8

|

1200

|

200

|

20

|

26/Hr

|

|

DSRT-5000L

|

1700

x 2000

|

3700

|

7.5

|

9.5

|

1350

|

200

|

25

|

33/Hr

|

|

DSRT-6000L

|

1900

x 2000

|

4500

|

11

|

11

|

1300

|

250

|

30

|

39/Hr

|

|

DSRT-7000L

|

1900

x 2200

|

5000

|

11

|

12

|

1450

|

300

|

35

|

46/Hr

|

|

DSRT-8000L

|

2000

x 2300

|

5700

|

11

|

13

|

1500

|

300

|

40

|

52/Hr

|

|

DSRT-10000L

|

2200

x 2400

|

7500

|

15

|

15.5

|

1600

|

350

|

50

|

65/Hr

|

|

DSRT-12000L

|

2400

x 2500

|

9300

|

15

|

18

|

1650

|

400

|

55

|

72/Hr

|

|

DSRT-14000L

|

2400

x 2700

|

10000

|

15

|

19

|

1800

|

400

|

65

|

85/Hr

|

|

DSRT-15000L

|

2500

x 2700

|

11000

|

22

|

20

|

1800

|

450

|

70

|

91/Hr

|

|

DSRT-16000L

|

2500

x 3000

|

12000

|

22

|

21.5

|

2000

|

500

|

75

|

98/Hr

|

|

DSRT-18000L

|

2600

x 3000

|

13000

|

22

|

23

|

2000

|

500

|

80

|

105/Hr

|

|

DSRT-20000L

|

2600

x 3500

|

15000

|

22

|

25

|

2350

|

600

|

90

|

120/Hr

|

용도

- Homo & copolymer emulsions

- phenolic resins

- urea-formaldehyde resins

- melamine resins

- polystyrenes

- plasticisers

- alkyd resins

- stand oils

- polyester & epoxy resins

- varnishes

- esterifications

- low temperature resins in general

- high temperature resins in general

|

|

| [ 연락처 정보 ] |

Company Company |

Daesung Chemical Machinery Ind. Co. |

Address Address |

경기도 화성시 마도면 쌍송리 691-7번지 마도산업단지 16-6블럭

(우:445-861) 한국 |

Phone Phone |

82 - 31 - 3556348 |

Fax Fax |

82 - 31 - 3554696 |

Homepage Homepage |

|

Contact Contact |

Kyoung-Seob Lee / General Manager |

|

|

|

| |

|

Copyright(c) Daesung Chemical Machinery Ind. Co. All

Rights Reserved.

Tel : 82-31-355-6348 Fax : 82-31-355-4696 |

|

|

|

|